Thermal Straps & Technologies

Prioritize Thermal Performance

SDL has designed, built, and tested space and airborne instruments since 1959, and we understand the importance of thermal engineering. Our thermal management team, including heat transfer and cryogenic engineering experts, has developed the solderless thermal strap and other proven solutions to the challenges faced by spacecraft developers.

SDL thermal solutions include design, fabrication, and testing—all performed on site. Our expertise, in-house facilities, support services, and AS9100D certification ensure we meet the most stringent requirements for thermal components as well as complete thermal subsystems.

Thermal Straps

SDL first developed thermal strap technology in 1994 when we designed, built, and tested the SABER instrument, which is still on orbit and has performed flawlessly since 2001. Since then, we have continued to pioneer solderless flexible thermal straps and supporting technologies, including cutting-edge PGS thermal straps for mass-sensitive applications operating above ~80 K.

Our thermal experts work closely with customers to meet their specific needs, including complex end-block and foil/braid geometry, gold/nickel coating, multi-layer insulation (MLI) blanketing, tight schedules, large quantities, and demanding quality assurance requirements. Our affordable solutions provide high performance and eliminate joining materials that can wick into foil/braid, which prevents contamination control and service life issues.

Thermal Straps

SDL first developed thermal strap technology in 1994 when we designed, built, and tested the SABER instrument, which is still on orbit and has performed flawlessly since 2001. Since then, we have continued to pioneer solderless flexible thermal straps and supporting technologies, including cutting-edge PGS thermal straps for mass-sensitive applications operating above ~80 K.

Our thermal experts work closely with customers to meet their specific needs, including complex end-block and foil/braid geometry, gold/nickel coating, multi-layer insulation (MLI) blanketing, tight schedules, large quantities, and demanding quality assurance requirements. Our affordable solutions provide high performance and eliminate joining materials that can wick into foil/braid, which prevents contamination control and service life issues.

Thermal Subsystems

In addition to performing thermal engineering on our own instruments and spacecraft, SDL provides thermal subsystems to customers. These subsystems include radiators with integrated thermal straps and structural supports, cryogenic dewar systems, and thermoelectric cooler-controlled subsystems for precision temperature control. SDL also designs, fabricates, and applies MLI blanketing.

We are experts at the analyses required for these systems as well as testing to verify thermal and structural performance. SDL offers thermal vacuum testing and vibration testing services on site and commonly correlates analytical models to test results as part of the verification process.

Thermal Subsystems

In addition to performing thermal engineering on our own instruments and spacecraft, SDL provides thermal subsystems to customers. These subsystems include radiators with integrated thermal straps and structural supports, cryogenic dewar systems, and thermoelectric cooler-controlled subsystems for precision temperature control. SDL also designs, fabricates, and applies MLI blanketing.

We are experts at the analyses required for these systems as well as testing to verify thermal and structural performance. SDL offers thermal vacuum testing and vibration testing services on site and commonly correlates analytical models to test results as part of the verification process.

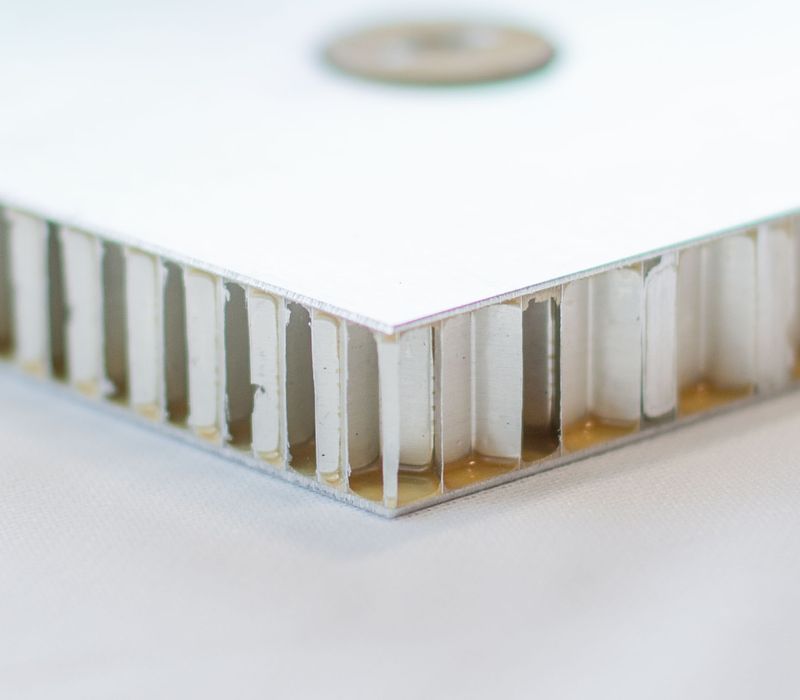

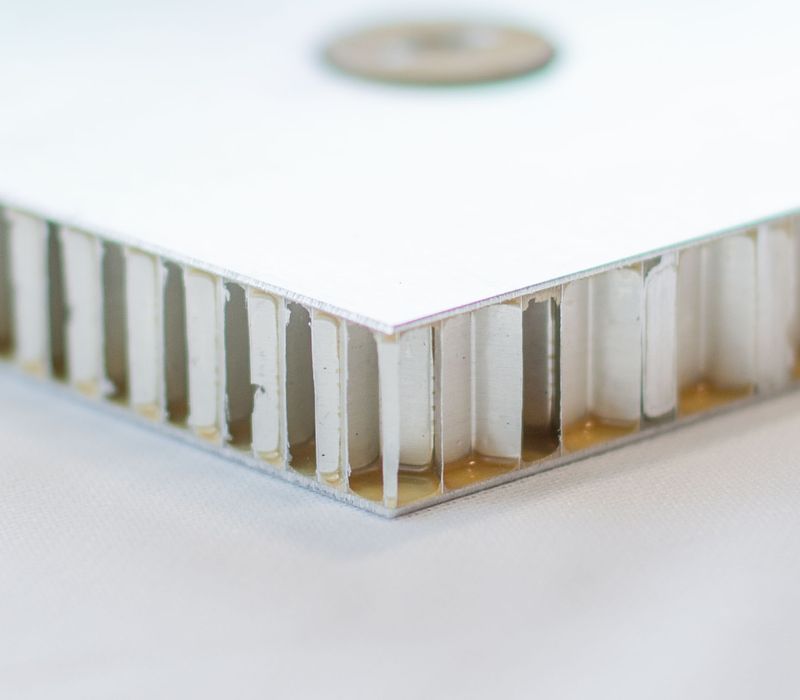

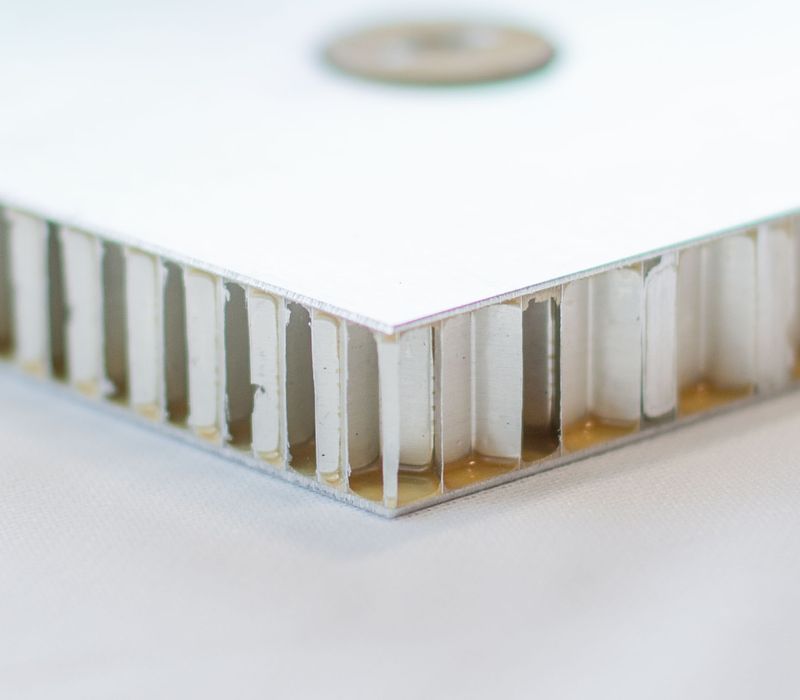

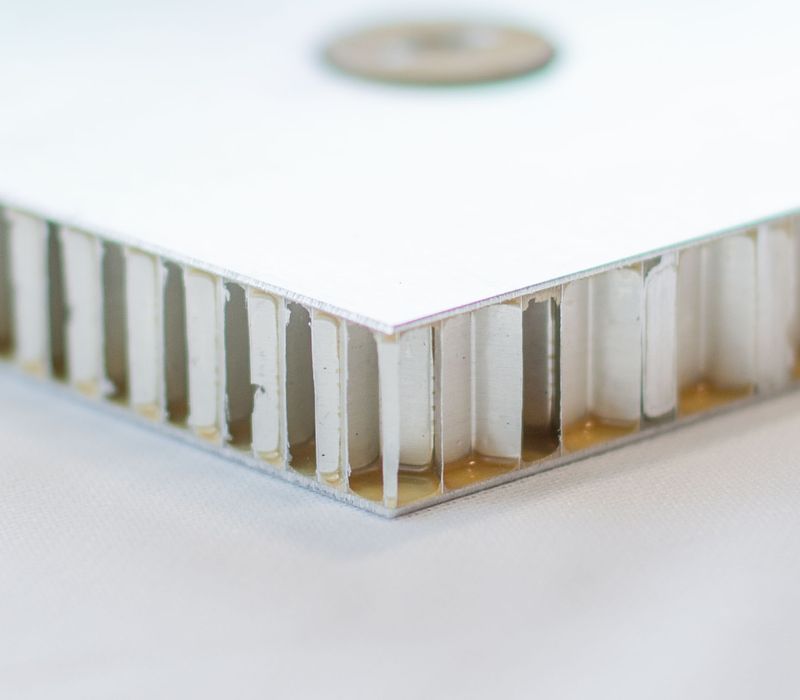

Honeycomb Radiators

SDL designs and fabricates honeycomb radiators, including application of some paints. We have the facilities and experienced staff to perform this work including in-house prototyping, structural testing, and analysis.

Honeycomb Radiators

SDL designs and fabricates honeycomb radiators, including application of some paints. We have the facilities and experienced staff to perform this work including in-house prototyping, structural testing, and analysis.

Thermal Conductor Bars

Pyrolytic Graphite Sheets (PGS) conductor bar technology combines the superior thermal performance of PGS with the rigid structural integrity of aluminum. Many applications demand a rigid conductor bar to efficiently remove heat from multiple sources simultaneously while providing structural support. SDL PGS conductor bars significantly outperform traditional aluminum conductor bars, with more than double the measured mass-specific thermal conductance. Optimization for specific customer interfaces can further increase performance.

Thermal Conductor Bars

Pyrolytic Graphite Sheets (PGS) conductor bar technology combines the superior thermal performance of PGS with the rigid structural integrity of aluminum. Many applications demand a rigid conductor bar to efficiently remove heat from multiple sources simultaneously while providing structural support. SDL PGS conductor bars significantly outperform traditional aluminum conductor bars, with more than double the measured mass-specific thermal conductance. Optimization for specific customer interfaces can further increase performance.

Thermal Straps

SDL first developed thermal strap technology in 1994 when we designed, built, and tested the SABER instrument, which is still on orbit and has performed flawlessly since 2001. Since then, we have continued to pioneer solderless flexible thermal straps and supporting technologies, including cutting-edge PGS thermal straps for mass-sensitive applications operating above ~80 K.

Our thermal experts work closely with customers to meet their specific needs, including complex end-block and foil/braid geometry, gold/nickel coating, multi-layer insulation (MLI) blanketing, tight schedules, large quantities, and demanding quality assurance requirements. Our affordable solutions provide high performance and eliminate joining materials that can wick into foil/braid, which prevents contamination control and service life issues.

Thermal Straps

SDL first developed thermal strap technology in 1994 when we designed, built, and tested the SABER instrument, which is still on orbit and has performed flawlessly since 2001. Since then, we have continued to pioneer solderless flexible thermal straps and supporting technologies, including cutting-edge PGS thermal straps for mass-sensitive applications operating above ~80 K.

Our thermal experts work closely with customers to meet their specific needs, including complex end-block and foil/braid geometry, gold/nickel coating, multi-layer insulation (MLI) blanketing, tight schedules, large quantities, and demanding quality assurance requirements. Our affordable solutions provide high performance and eliminate joining materials that can wick into foil/braid, which prevents contamination control and service life issues.

Thermal Subsystems

In addition to performing thermal engineering on our own instruments and spacecraft, SDL provides thermal subsystems to customers. These subsystems include radiators with integrated thermal straps and structural supports, cryogenic dewar systems, and thermoelectric cooler-controlled subsystems for precision temperature control. SDL also designs, fabricates, and applies MLI blanketing.

We are experts at the analyses required for these systems as well as testing to verify thermal and structural performance. SDL offers thermal vacuum testing and vibration testing services on site and commonly correlates analytical models to test results as part of the verification process.

Thermal Subsystems

In addition to performing thermal engineering on our own instruments and spacecraft, SDL provides thermal subsystems to customers. These subsystems include radiators with integrated thermal straps and structural supports, cryogenic dewar systems, and thermoelectric cooler-controlled subsystems for precision temperature control. SDL also designs, fabricates, and applies MLI blanketing.

We are experts at the analyses required for these systems as well as testing to verify thermal and structural performance. SDL offers thermal vacuum testing and vibration testing services on site and commonly correlates analytical models to test results as part of the verification process.

Honeycomb Radiators

SDL designs and fabricates honeycomb radiators, including application of some paints. We have the facilities and experienced staff to perform this work including in-house prototyping, structural testing, and analysis.

Honeycomb Radiators

SDL designs and fabricates honeycomb radiators, including application of some paints. We have the facilities and experienced staff to perform this work including in-house prototyping, structural testing, and analysis.

Thermal Conductor Bars

Pyrolytic Graphite Sheets (PGS) conductor bar technology combines the superior thermal performance of PGS with the rigid structural integrity of aluminum. Many applications demand a rigid conductor bar to efficiently remove heat from multiple sources simultaneously while providing structural support. SDL PGS conductor bars significantly outperform traditional aluminum conductor bars, with more than double the measured mass-specific thermal conductance. Optimization for specific customer interfaces can further increase performance.

Thermal Conductor Bars

Pyrolytic Graphite Sheets (PGS) conductor bar technology combines the superior thermal performance of PGS with the rigid structural integrity of aluminum. Many applications demand a rigid conductor bar to efficiently remove heat from multiple sources simultaneously while providing structural support. SDL PGS conductor bars significantly outperform traditional aluminum conductor bars, with more than double the measured mass-specific thermal conductance. Optimization for specific customer interfaces can further increase performance.